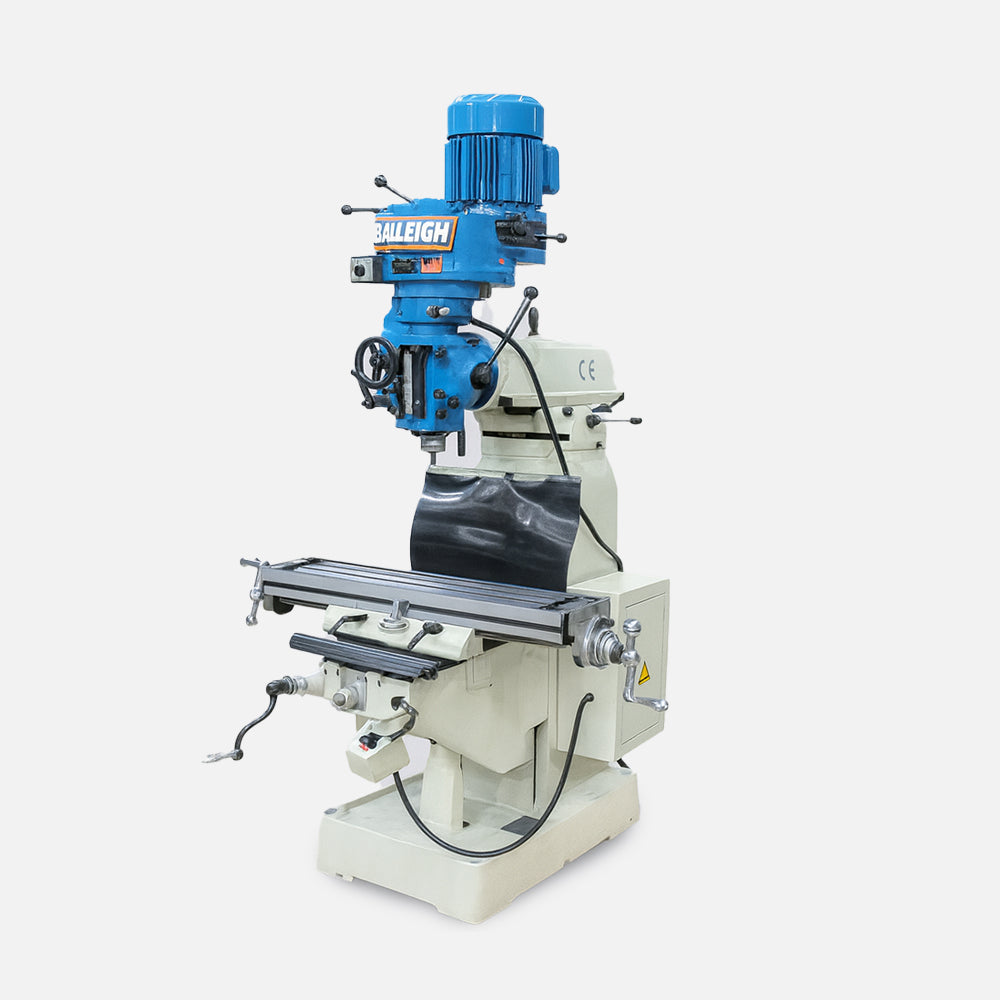

Precision Drilling and Milling in One Versatile Machine

3-Axis DRO | 16 Spindle Speeds | 3HP Motor | 10" x 50" Table | Complete Machining Solution

When your shop needs the versatility to handle both precision drilling and complex milling operations without the space or budget for separate machines, the MX1050 delivers professional-grade capability in one integrated platform. This dual-purpose machine transforms your workflow by eliminating workpiece transfers between drilling and milling operations while maintaining the accuracy that precision work demands.

Professional Digital Readout System

3-Axis DRO (Digital Readout) provides precise position feedback for all table movements, enabling repeatable accuracy and efficient setup for complex machining operations. This digital positioning system eliminates the guesswork and measurement errors that plague manual operations, ensuring consistent results across production runs.

Comprehensive Spindle Speed Range

16 belt-driven spindle speeds from 150 to 5,440 RPM cover the complete range from heavy drilling in steel to high-speed finishing operations in aluminum. This extensive speed range eliminates the compromises that force shops to choose between drilling capability and milling performance.

R8 spindle taper provides secure tooling retention with extensive tooling compatibility, from precision drilling bits to heavy-duty end mills and face mills.

Substantial Machining Capacity

10" x 50" table with hardened surface and T-slot configuration handles substantial workpieces while providing secure clamping capability. Three T-slots at 2.5" centers with 5/8" width accommodate standard clamping hardware for versatile workholding solutions.

Drilling Capabilities:

- Steel: 1.25" maximum diameter

- Iron: 1.5" maximum diameter

- End Milling: 1" maximum capacity

- Face Milling: 3" maximum capacity

Advanced Feed Control Systems

Automatic downward feed with three precision rates (0.0015, 0.003, 0.006 in./rev.) enables consistent drilling operations while reducing operator fatigue. The precision quill feed system provides smooth, controlled advancement for both drilling and milling operations.

Longitudinal power feed automates table movement during milling operations, ensuring consistent surface finish and reducing manual operation requirements.

Maximum Operational Flexibility

Head swivel capability (90° left/right) and tilt function (45° front/back) enable compound angle operations without complex fixturing. The 360° turret swivel provides complete positioning flexibility for accessing all sides of complex workpieces.

Ram travel of 18.5" extends reach for deep workpieces, while 5" spindle travel accommodates varying workpiece heights without repositioning.

Comprehensive Travel Ranges

Longitudinal (X-Axis): 29.5" table travel

Cross (Y-Axis): 15.75" table travel

Vertical (Z-Axis): 15.75" knee travel

These generous travel ranges handle substantial workpieces while maintaining precision positioning throughout the working envelope.

Professional Operating Features

Coolant recycling system maintains cutting tool temperatures and extends tool life while improving surface finish quality. The integrated system eliminates the mess and waste associated with flood coolant applications.

Forward and reverse spindle switch enables tapping operations and provides flexibility for specialized cutting operations.

Micro-adjustment capability with automatic head stopping provides precise positioning control for critical operations.

Longitudinal limit switch protects the worktable from overtravel, preventing damage to machine components and workpieces.

Quality Construction Details

Chrome-plated handles improve operator comfort and provide corrosion resistance for long-term durability. Hand lubrication points ensure proper maintenance accessibility for extended machine life.

Hardened table surface resists wear and maintains accuracy through extended use, while the substantial 2,464-pound machine weight provides vibration dampening for smooth operation.

Power and Electrical Specifications

3 HP single-phase 230V motor provides reliable power for demanding operations while fitting standard shop electrical requirements. 16-amp electrical demand enables operation with standard shop wiring configurations.

Complete Ready-to-Run Package

Includes service tools and toolbox for immediate operation and ongoing maintenance. Professional installation and commissioning video ensures proper setup for optimal performance and safety.

What This Means for Your Machine Shop

The MX1050 eliminates the need for separate drilling and milling machines while providing the accuracy and capability that precision work demands. Workpieces stay in one setup for both drilling and milling operations, reducing handling time and improving accuracy.

The combination of digital readout positioning, comprehensive speed range, and advanced feed systems enables complex operations that would require multiple machines or extensive manual work on conventional equipment.

Applications That Demand Versatility

Tool and Die Making: Precision drilling and milling for tooling applications

General Machine Shop: Versatile capability for diverse customer requirements

Maintenance Operations: Complete machining capability for repair and modification work

Production Manufacturing: Efficient drilling and milling for medium-volume production

Educational Training: Comprehensive machine tool training on industry-standard equipment

Investment in Shop Capability

The MX1050 represents significant capability expansion in a single machine footprint. Rather than investing in separate drilling and milling equipment, this integrated solution provides both capabilities with the accuracy and features that professional work demands.

Ready to Expand Your Machining Capabilities?

When versatility and precision matter, the MX1050 Multiple Speed Vertical Turret Drill Milling Machine delivers professional-grade drilling and milling capability in one integrated platform.

Transform your machining workflow with the efficiency and accuracy that integrated drilling and milling provides.