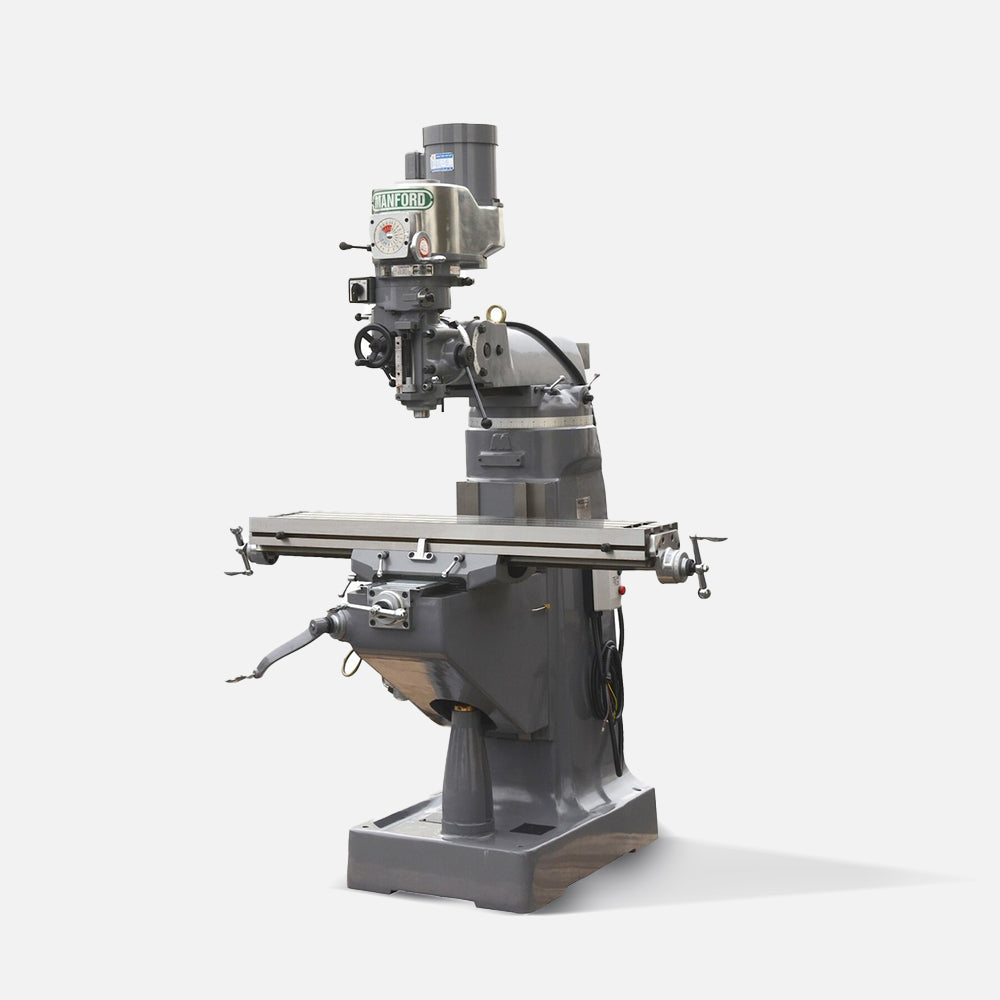

American-Made Precision for Professional Machining

9" x 49" Table | Variable Speed Control | Three-Phase Power | Made in USA

When your machine shop demands reliable precision milling capability with the flexibility to handle diverse materials and operations, this American-made knee milling machine delivers the performance and durability that professional machining requires. Built to traditional milling machine standards with modern refinements, this machine provides the foundation for precision work that stands the test of time.

Substantial Working Capacity

The generous 9" x 49" table provides ample workspace for substantial components while maintaining the rigidity needed for precision machining. This table size accommodates most production work and prototype development while fitting efficiently into standard shop layouts.

Comprehensive Travel Ranges

Longitudinal Travel: 36 inches of X-axis movement handles long workpieces and multiple-part setups efficiently

Cross Travel: 12 inches of Y-axis travel provides substantial width capacity for complex components

Knee Travel: 16 inches of vertical movement accommodates varying workpiece heights while maintaining full machining capability throughout the working envelope

Variable Speed Flexibility

Variable speed pulley system enables optimization for different materials and cutting conditions without the complexity of electronic controls. This mechanical speed variation provides reliable, consistent power delivery across the speed range while offering the simplicity and durability that professional shops demand.

The variable speed capability allows operators to match cutting speeds to specific materials and tooling requirements, maximizing tool life while achieving optimal surface finishes and dimensional accuracy.

Professional Three-Phase Power

Three-phase electrical configuration ensures consistent motor performance and efficiency suitable for continuous production environments. This industrial power requirement reflects the machine's professional-grade construction and capability.

American Manufacturing Quality

Made in USA construction ensures quality standards and manufacturing practices that meet the demands of professional machining environments. Domestic manufacturing provides reliable parts availability and service support throughout the machine's operational life.

Traditional Knee Mill Design

Time-tested knee mill configuration provides the versatility and capability that has made this design the standard for precision machining operations. The knee mill format enables complex machining operations with multiple setups while maintaining the accuracy needed for demanding applications.

This proven design offers the flexibility to handle drilling, boring, slotting, and complex milling operations on a single platform, eliminating the need for multiple specialized machines in many applications.

Professional Shop Integration

The machine's specifications and design make it ideal for integration into existing shop workflows where reliable milling capability is essential. Whether supporting production operations or enabling prototype development, this machine provides the capability and consistency that professional work demands.

Standard shop electrical requirements and conventional operating procedures ensure smooth integration without extensive retraining or infrastructure modifications.

Investment in Proven Technology

This knee milling machine represents investment in proven technology that delivers consistent results year after year. The combination of substantial capacity, variable speed flexibility, and traditional reliability provides long-term value that supports shop growth and capability expansion.

Applications for Professional Machining

General Machine Shop Operations: Versatile milling capability for diverse customer requirements

Production Manufacturing: Reliable precision for medium-volume production runs

Tool and Die Work: Precision machining for tooling applications requiring accuracy

Maintenance and Repair: Complete milling capability for equipment modification and repair

Prototype Development: Flexible machining for development and testing applications

Proven Performance for Demanding Work

The traditional knee mill design has proven itself across decades of professional use, providing the versatility and accuracy that modern machining operations continue to demand. This machine maintains that proven performance while incorporating the refinements needed for contemporary shop efficiency.

Ready to Add Proven Milling Capability?

When reliable precision milling capability matters, this American-made knee milling machine delivers the performance and durability that professional shops trust.

Experience the reliability and precision that proven engineering provides for your machining operations.